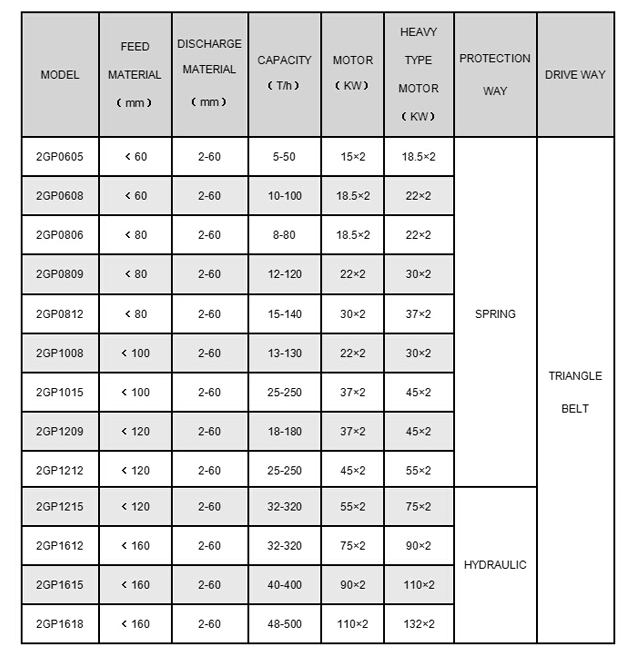

2GP series roll crusher

2GP series roll crusher is suitable for compressive strength less than 200Mpa, moisture content less than 15% of medium-hard and hard materials crushed and crushing operations. Quite above hardness of solid materials such as cement clinker, coal, coke, slag, slag, gypsum, clay, chemical raw materials, low maintenance costs, power consumption, reliable performance, less dust, low noise characteristics. Standard heavier type can be divided according to the material hardness.

A. standard

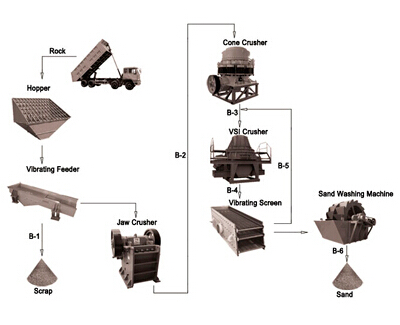

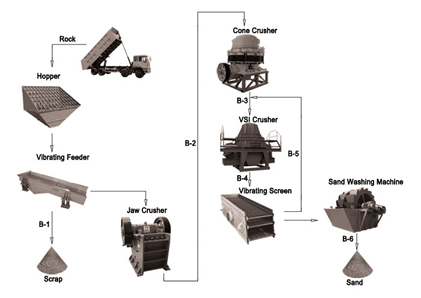

Two grinding roller machine configuration, using cone roller surface welding surface, suitable for feed size less than 160mm, 2-60mm finished size requirements crushing operations. Such as pre-crushing cement clinker with a variety of composite materials in the cement industry mill before; the boiler slag crushed the reuse, the crushing of power plant ashes do unburned brick or similar broken occasions.

B, heavier type

Two grinding roller machine configuration, using cone roller surface welding surface, suitable for feed size less than 160mm, 2-60mm finished size requirements crushing operations. Pre-crushing metal industry into the mill steel slag, iron ore, silicon ore, cobblestone, construction waste artificial sand making all kinds of stone crushing after doing unburned brick or similar broken occasions.

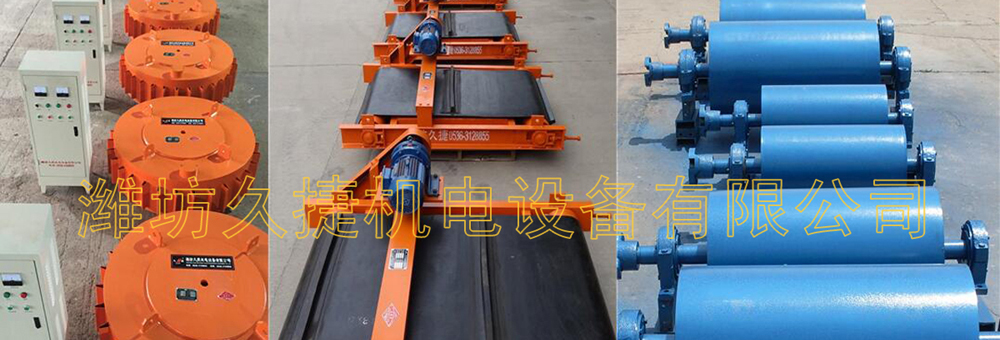

1. the roller body 45 carbon steel casting roll surface after machining cone welded with wear-resistant materials, cone weld cooling after hardness (HRC) of 60-76 degrees, the wear layer thickness of 6-20 mm, with a resistancegood wear resistance, impact resistance, the service life of 4000-9000 hours (according to the hardness of the material), the wear layer after grinding concave, wear-resistant materials the roller surface repair can be re-used, without having to replace the roller.

2. Machine spring (or hydraulic system) to set the protection function in case of rigid or non-broken material, the activities of the rolls automatically concede, excellent or non-broken material falling, the machine automatically return to work to protect the machine from damage.

3. adjust the gap of the two rollers, broken particle size can be controlled and changed production capacity and set a unique two-roll gap adjustment scale (broken particle size) display function, to prevent user replaceable bearings tune partial bearing.

4. Really use ZWZ and SKF (the world's first brand) joint bearings, and the outer and inner layers of imported oil seal skeleton structure, to prevent the machine inside of the dust of the long-term continuous operation in harsh environments, the damage to the bearings.

5. the machine configuration unpowered fabric machine, so that the material around evenly into the machine to prevent partial wear roller surface, but also make the crushing uniform particle size and improve crushing efficiency.

6. the normal operation of the machine settings without power scrapers and differential work, non-stick roller machine when the material moisture, non-blocking materials, broken particle size and machine.

2GP series of roll crusher is the use of high-strength wear-resistant alloy mill roll relative rotation of the rolling and Nie high extrusion pressure to break material, after the material into the crushing chamber, the pressure by the relative rotation of the grinding rollers squeeze, squeezeunder the mill, the material to break into ideal particle discharge.

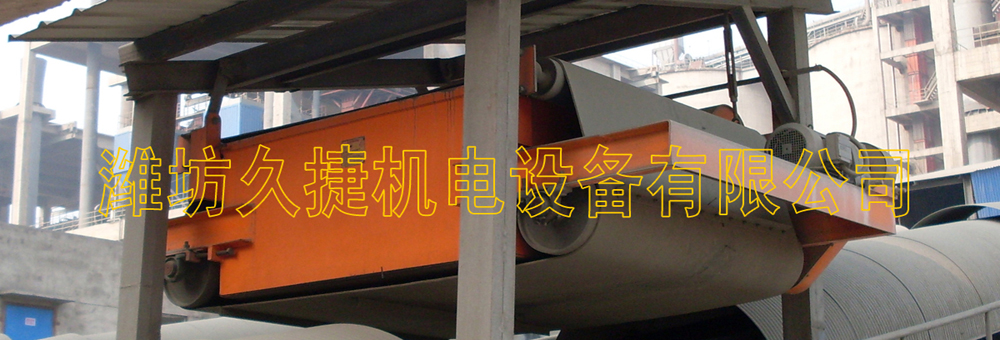

USE SITE: