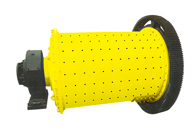

Ball Mill

Ball mill is mainly used to grind materials in mineral, cement, refractory, chemical industry, etc. Ball mill has dry and wet ways. When wet ball mill works, certain water

and other liquid will be added with materials to increase materials liquidity, so the capacity is increased. When dry ball mill works, the reduced material liquidity will

influence the productivity. So absorbing wind device is needed on the outlet of ball mill, and then negative pressure is formed inside the ball mill to increase flow ability

of material, at last the capacity is increased.

| Model | Speed (r/min) | Max. weight of balls (t) | Input size (mm) | Output size (mm) | power (kw) | Capacity (t/h) | Weight(t) |

| Φ900×1800 | 37 | 1.8 | ≤15 | 0.075-0.89 | 15 | 0.5-2 | 3.4 |

| Φ900×2100 | 37 | 2.3 | ≤15 | 0.075-0.4 | 18.5 | 0.4-2 | 3.9 |

| Φ900×3000 | 35 | 3.85 | ≤25 | 0.075-0.4 | 30 | 1.1-2.5 | 7.78 |

| Φ1200×2400 | 35 | 4.6 | ≤25 | 0.075-0.4 | 30 | 1.3-3.2 | 8.65 |

| Φ1200×2800 | 35 | 5.4 | ≤25 | 0.075-0.4 | 37 | 1.5-3.7 | 10.02 |

| Φ1200×4500 | 35 | 8.6 | ≤25 | 0.075-0.4 | 45 | 2.7-6.79 | 14 |

| Φ1500×3000 | 29 | 9 | ≤25 | 0.047-0.4 | 75 | 3.3-8.2 | 14.12 |

| Φ1500×3500 | 29 | 10.5 | ≤25 | 0.047-0.4 | 75 | 3.3-8.5 | 15.64 |

| Φ1500×4500 | 29 | 13.5 | ≤25 | 0.047-0.4 | 90 | 4.5-12 | 20 |

| Φ1500×5700 | 29 | 17 | ≤25 | 0.047-0.4 | 110 | 2.6-14 | 21.5 |

| Φ1830×3000 | 24 | 13.5 | ≤25 | 0.047-0.4 | 135 | 4-15 | 28 |

| Φ1830×3600 | 24 | 14 | ≤25 | 0.047-0.4 | 135 | 4-15 | 29 |

| Φ1830×4500 | 24 | 20 | ≤25 | 0.047-0.4 | 155 | 4-19 | 32 |

| Φ1830×7000 | 24 | 31.5 | ≤25 | 0.047-0.4 | 210 | 6-22 | 37.5 |

| Φ2100×3000 | 22 | 18 | ≤25 | 0.047-0.4 | 210 | 6.4-28 | 40.79 |

| Φ2100x3600 | 22 | 20 | ≤25 | 0.047-0.4 | 210 | 7-28 | 42 |

| Φ2100×4000 | 22 | 21.5 | ≤25 | 0.047-0.4 | 210 | 7.6-28 | 43.45 |

| Φ2200×3600 | 21.7 | 25 | ≤25 | 0.047-0.4 | 245 | 5.2-32 | 44 |

| Φ2200×7000 | 21.7 | 46 | ≤25 | 0.047-0.4 | 380 | 15-38 | 63 |

| Φ2400×3600 | 21 | 28 | ≤25 | 0.047-0.4 | 320 | 8-60 | 47 |

| Φ2400×4500 | 21 | 35 | ≤25 | 0.047-0.4 | 380 | 8.5-60 | 70.5 |

| Φ2700×3600 | 20.7 | 40 | ≤25 | 0.047-0.4 | 400 | 12-80 | 75.5 |

| Φ2700×4500 | 20.7 | 48 | ≤25 | 0.047-0.4 | 450 | 12-90 | 102 |

| Φ3200×4000 | 18 | 65 | ≤25 | 0.047-0.4 | 800 | 30-180 | 110 |