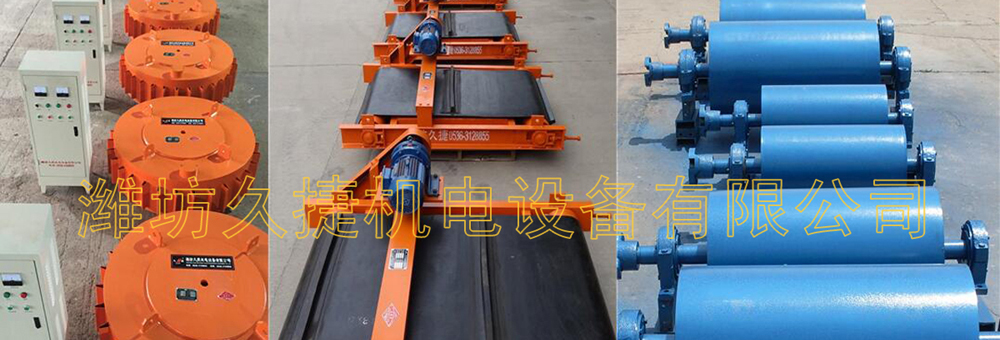

CTS(NB) Series Magnetic drum separators

CTS (NB) Serieswet Permanent Magnet Separatorisapplicable tothemining, coal preparation plant andother units, forwetweak magnetic fieldsortingoffine-grainedferromagnetic minerals, orremovethenon-magneticmineralmixture ofstrongmagnetic minerals.

The CTS, CTN and CTB series permanent magnetic cylinder separators have two kinds of structures: rotary and fixed.

The fixed one is suitable for choosing fine strong-magnetic particles in wet and weak magnetic fields. It also can be used to remove the strong-magnetic minerals among non-magnetic minerals. When the slurry flows into the magnetic field, the strong-magnetic minerals are adsorbed on the surface of the cylinder, and the weak-magnetic and non-magnetic minerals are sorted out. And then, the strong-magnetic minerals are brought out of the magnetic field with the cylinder rotating. The rotary one is suitable for choosing fine strong-magnetic (moderately strong-magnetic) particles in dry condition. Due to the high speed rotation, the roll number of the magnetic particle is much higher than the ordinary magnetic separator’s. This has a significant effect on destroying the magnetic agglomeration and improving the rich ore ratio. After separating, the minerals are sorted into magnetic and non-magnetic and excluded from their own mouth. The rotary one is applicable to the rough selection and concentration of the ore particle size of 0.6-6mm.

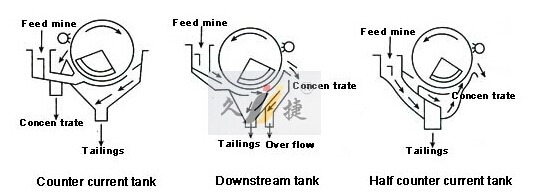

The one cylinder can be equipped with three types of tank, namely downstream launder (CTS) classification size≤6mm, countercurrent launder (CTN) classification size ≤0.6mm and semi-countercurrent launder (CTB) classification size≤1mm.

1. Adopt advanced magnetic circuit design. The magnetic material is made of magnetic materials with high remanence and high coercivity. They have a very good resistance to demagnetization, providing a strong guarantee for the magnetic effect.

2. With aluminum end caps, stainless steel flange wear

3. Modular structure, easy to install, and easy to adjust the magnetic declination

4. Advanced design, brand motor, reducer and SKF bearing, ensuring the machine runs stably for a long term.

5. The whole machine is made of high-quality material, beautiful and practical.

6. Providing the following common parts according to the customer requirements: 1. bearing, 2. seal, 3. motor, reducer, 4. the active and driven chains, 5. outer drum skin

Machine Installation, Adjustment and Commissioning

Installation and Adjustment

1、To check and make sure that all parts should be consistent with the technical conditions of the drawings.

2、The permanent magnetic cylinder, the parts, each dimension, installation and adjustment should be strictly inspected.

3、Each parts should have no serious magnetic damage or variable defects.

4、To check the parts quantity and clean oil according to the drawings and documents.

Commissioning

1、After installing, the machine has to run for no less than two hours without being fed ore.

2、Before operating, the motor reducer, sealed box, bearing fastening screws should be firm, and the contact surface should be close, no wound foot phenomenon.

3, The roller bearings at both ends of the cylinder must have enough lubricating oil. The reducer has moderate lubricating oil. The adjustment screw of the magnetic system has grease.

4, The cylinder is moved by hand so it has flexible rotation without distortions and abnormal sounds.

5, After being filled with grease, it should continue to test for 1 hour and the sealing box has no oil leakage, no abnormal sounds and vibration.

6, During the commissioning, if the abnormal phenomenons of the cylinder and the transmission parts are found, they should be examined and promptly repaired.

The machine has three tank: half countercurrent tank (CTB); downstream tank (CTS) and countercurrent tank (CTN), applicable to the requirements of the different options particle size and different election process.

Product features are: the use of computer optimized design, magnetic circuit, and strict selection of high coercivity, high remanence NdFeB rare earth permanent magnets, magnetic ensure a long period of time without reducing the safeguard of long-term interests, the overall structure of reliable and durable. When the slurry injected into the magnetic field, where strong magnetic mineral is adsorbed on the cylinder surface, the weak magnetic and non-magnetic minerals are successively exclude adsorption in a strong magnetic minerals of the cylinder with the rotation of the cylinder was taken out of the magnetic field.

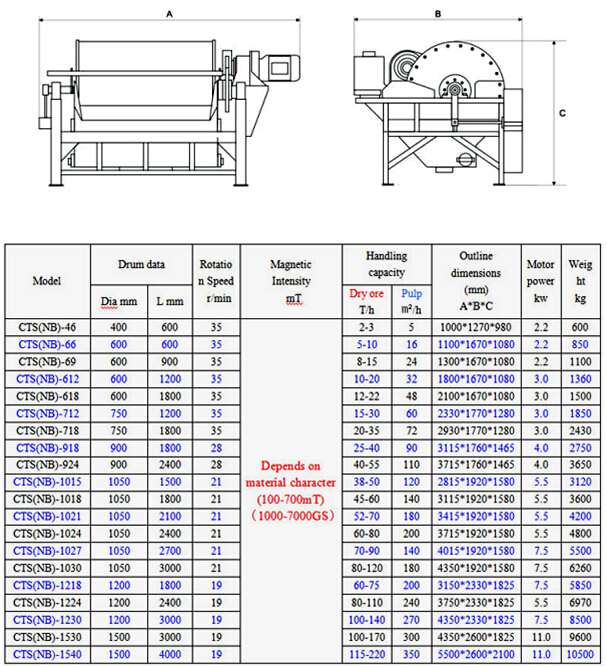

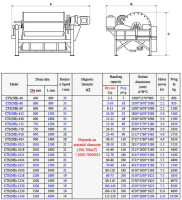

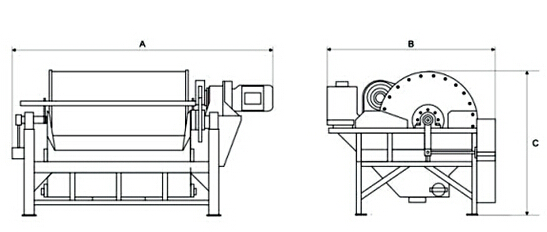

Parameter table:

Model | Drum data |

Rotation Speed r/min | Magnetic Inernsity mT | Handling capacity | Outline dimensions (mm) A*B*C | Motor power kw | Weight Kg

| ||

Dia mm | L mm | Dry ore T/h | Pulp ㎡/h | ||||||

CTS(NB)-46 | 400 | 600 | 35 | Depends on material character (100-700mT) (1000-7000GS) | 2-3 | 5 | 1000*1270*980 | 2.2 | 600 |

CTS(NB)-66 | 600 | 600 | 35 | 5-10 | 16 | 1100*1670*1080 | 2.2 | 850 | |

CTS(NB)-69 | 600 | 900 | 35 | 8-15 | 24 | 1300*1670*1080 | 2.2 | 1100 | |

CTS(NB)-612 | 600 | 1200 | 35 | 10-20 | 32 | 1800*1670*1080 | 3.0 | 1360 | |

CTS(NB)-618 | 600 | 1800 | 35 | 12-22 | 48 | 2100*1670*1080 | 3.0 | 1500 | |

CTS(NB)-712 | 750 | 1200 | 35 | 15-30 | 60 | 2330*1771*1280 | 3.0 | 1850 | |

CTS(NB)-718 | 750 | 1800 | 35 | 20-35 | 72 | 2930*1770*1280 | 3.0 | 2430 | |

CTS(NB)-918 | 900 | 1800 | 28 | 25-40 | 90 | 3115*1760*1465 | 4.0 | 2750 | |

CTS(NB)-924 | 900 | 2400 | 28 | 40-55 | 110 | 3715*1760*1465 | 4.0 | 3650 | |

CTS(NB)-1015 | 1050 | 1500 | 21 | 38-50 | 120 | 2815*1920*1580 | 5.5 | 3120 | |

CTS(NB)-1018 | 1050 | 1800 | 21 | 45-60 | 140 | 3115*1920*1580 | 5.5 | 3600 | |

CTS(NB)-1021 | 1050 | 2100 | 21 | 52-70 | 180 | 3415*1920*1580 | 5.5 | 4200 | |

CTS(NB)-1024 | 1050 | 2400 | 21 | 60-80 | 200 | 3715*1920*1580 | 5.5 | 4800 | |

CTS(NB)-1027 | 1050 | 2700 | 21 | 70-90 | 140 | 4015*1920*1580 | 7.5 | 5500 | |

CTS(NB)-1030 | 1050 | 3000 | 21 | 80-120 | 180 | 4350*1920*1580 | 7.5 | 6260 | |

CTS(NB)-1218 | 1200 | 1800 | 19 | 60-75 | 200 | 3150*2330*1825 | 7.5 | 5850 | |

CTS(NB)-1224 | 1200 | 2400 | 19 | 80-110 | 240 | 3750*2330*1825 | 5.5 | 6970 | |

CTS(NB)-1230 | 1200 | 3000 | 19 | 100-140 | 270 | 4350*2330*1825 | 7.5 | 8500 | |

CTS(NB)-1530 | 1500 | 3000 | 19 | 100-170 | 300 | 4350*2600*1825 | 11.0 | 9600 | |

CTS(NB)-1540 | 1500 | 4000 | 19 | 115-220 | 350 | 5500*2600*2100 | 11.0 | 10500 | |

NOTE:The maximum magnetic flux density values are based on the different minerals iron,The range of the magnetic field strength can be produced from 1000GS to 7000GS.

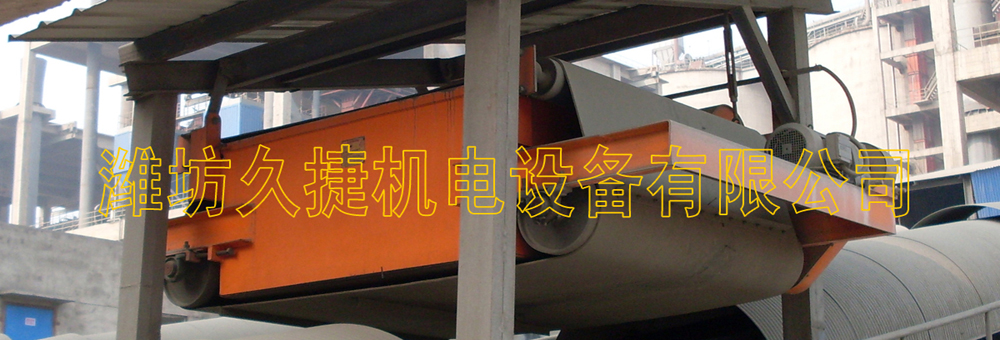

USE SITE: