CTD Series Dry Magnetic Separators

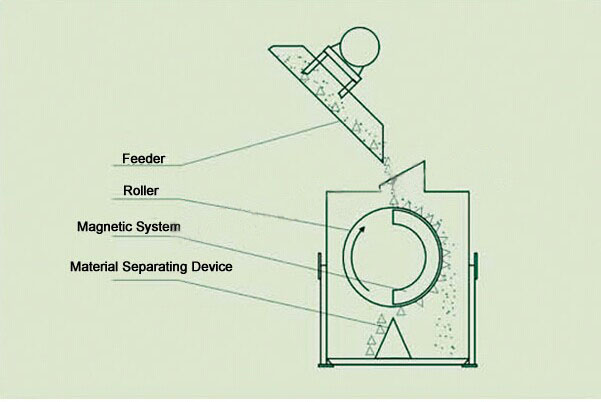

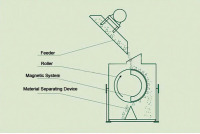

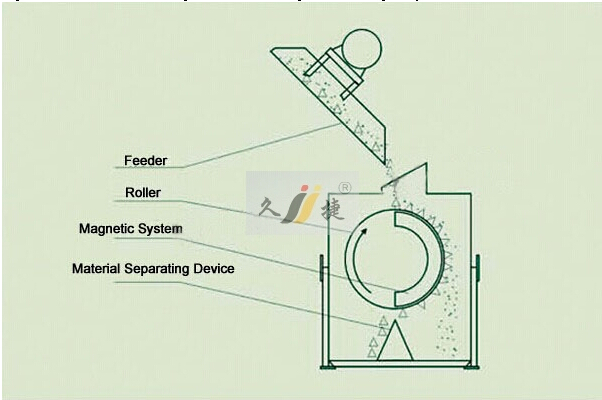

Dry magnetic separators are our company’s newly developed high-efficiency and successful magnetic separation equipments. The magnetic system all adopts high performance tin soil neodymium iron boron and ferrite material. With the open type and skillful magnetic circuit design: the highest magnetic induction strength of the cylinder surface’s sorting area can reach above 0.8T; The magnetic field strength is 3-5 times as much as conventional magnetic machine; The magnetic force of the sorting region can achieve the magnetic level of electromagnetic magnetic separator. The sorting cylinder is made of refined wear-resistant stainless steel. Sorting mineral adopts vibrating ore evenly to the upper part of the sorting feeder, the rotating cylinder throws off the non-magnetic material from the cylinder body, and the magnetic material is subjected to strong magnetic force and attracts to the cylinder, and then the magnetic and non magnetic material are separated easily and precisely by using mine division plate.

The strong magnetic force makes it real for dry magnetic separator to select magnetic and weak magnetic minerals. The equipment has strong processing capacity, wide grain size range of sorting mineral, high separation precision, no blockage; has the advantages of simple structure, convenient maintenance, and the power consumption is only 20% of the electromagnetic magnetic separator.

It applies the principle that a magnetic material can be attracted by permanent magnet to design semi circular magnetic series, forming a larger magnetic field in the interior of the roller flowed through by materials. When the materials flow through the magnetic field, magnetic ores are attracted by the magnetic force at once and adsorbed on the surface of the semicircle adsorption roller in the magnetic system. When the magnetic ores are taken to the non-magnetic bottom zone, they are discharged from concentrate mouth under the role of gravity. At the same time, the non-magnetic or lower iron-rate ores can pass through freely from the magnetic field and are discharged from the tailing mouth under gravity.

1. Separating without water: It is a dry magnetic separator so no water is needed. Compared with water separating, it has two advantages: no sewage sludge and saving water.

2. Good separation effect: Due to the design of the dynamic magnetic system of the machine, the ores slide on the roller’s surface, move and roll. The roller does not adhere materials, which is good for material separation. The primary sorting grade increases 1-4 times and one select grade can reach over 60%.

3. Large processing capacity: Because the company uses the parcel open magnetic system and the material does not wrap into a group, no blocking phenomenon, the processing capacity is large. The quantity of processing ore of a single selected machine can reach more than 50 tons. The multi machines also can be used in parallel connection, which can multiply the product quantity.

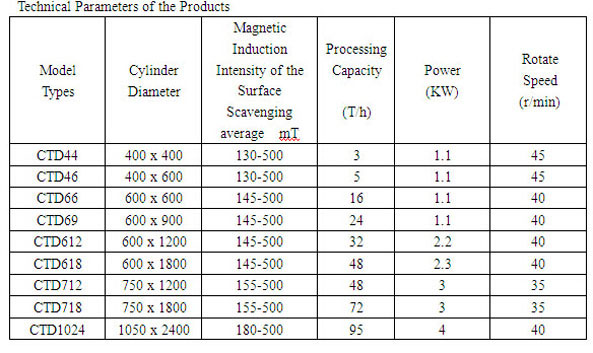

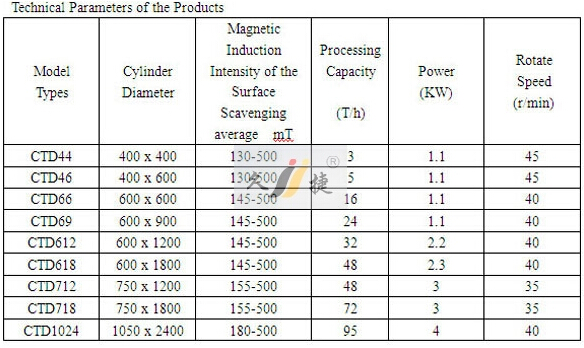

4. Extensive industry application: our company’s dry magnetic separators can be divided into four categories, with more than 20 varieties and specifications and models. These machines can meet the need of a variety of iron ores, sand, tailings, steel slag, steel ash, sulfuric acid residue, abrasives, fireproofing materials, plate making, rubber, food and other industries. Some equipments can be a machine with multi-use.

5. High production efficiency: dry selection needs no water. So it is not limited by the water source and can works all year round. For no-water area, seasonal water shortage area and high-cold area, the machine can increase 100-150 working days per year, effectively improve the utilization rate of equipment.

Pre-sale:

1 To configure a consistent type machine according to the customer's actual demand

2 To customize products according to the customer's special demand

3 Our company can send technical personnel to the user site to design site and the best procedure and planning.

Sale:

1 Strict inspection on the products before they go out

2 To deliver the products in accordance with the contract

After-sale:

1 Free training technical personnel for clients

2 According to the purchase contract, our company can send technical personnel to guide installation and adjustment for free.

3 The company supplies machine parts all year round.

4 The company collects customer’s feedback, timely formulates implementation plans to solve customer’s problems.

5 In case of unexpected problems, they can be solved within 24 hours from the company within 1000 kilometers. For those more than 1000 kilometers, we give satisfied reply within 24 hours.

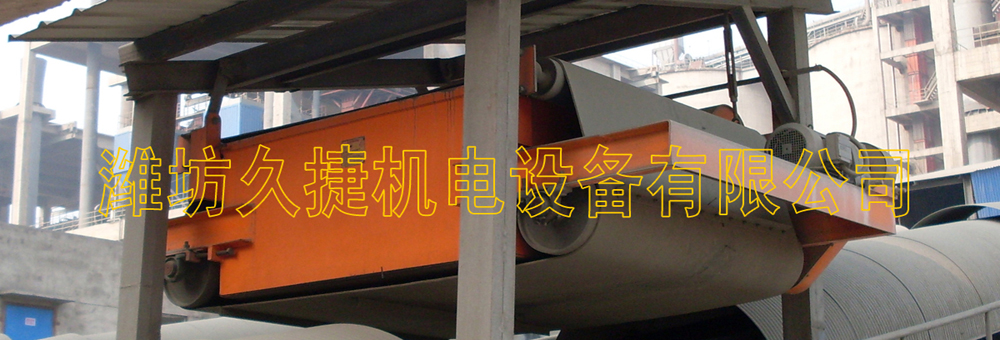

Our company's magnetic separation equipments mainly include plate type magnetic separators, CTB (S/N) series permanent magnetic drum separators, CTG series medium intensity permanent magnetic rotary drum and dry magnetic separators with good performance and wide utilization.