24 hours service hotline: 0086-15863612270

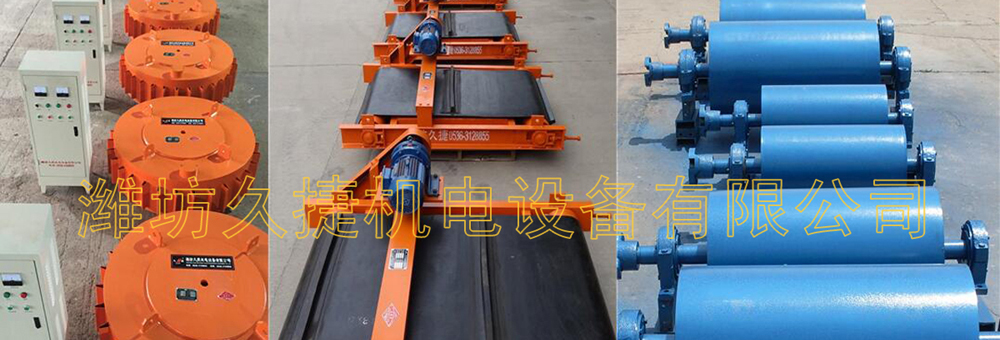

The model meaning of the lifting electromagnetic

Lifting Electromagnet knowledge:First, use

1, lifting steel and other permeable material used in metallurgy, mining, machinery, transportation and other industries.

2, as electromagnetic manipulator clamping steel permeable material.Second, the basic principles and conditions of use

1. The basic principles ofElectromagnet work, power and control equipment supplied to the electromagnets DC electromagnets internally generated a strong magnetic field, to produce powerful magnetic sucked through the the shell magnetic circuit and working air gap and achieve the purpose of the movement of materials.

2. Conditions of use

1) The place of use of the altitude over 2000 meters;

2) the surrounding medium temperature: no higher than +60 ° C, not lower than -20 ° C;

3) the surrounding work environment free of hazardous and non-corrosive gases;

4) ambient air relative humidity not more than 85% (20 ° C);

5) indoor and outdoor use.Third, the main features of

1, a fully sealed structure, moisture resistant.

2, computer optimization design, rational structure, light weight, suction, low energy consumption.Excitation coil with a special treatment process to improve the electrical and mechanical properties of the coil insulation material heat-resistant grade of C-class, suckers overall insulation of H-class, long life.

4 the common type electromagnet rated power sustained rate increased to 60% from 50% in the past to improve the efficiency in the use of the electromagnet.

5, the high-temperature type electromagnet unique insulation, which is the temperature of the suction was increased to 700 ° C from the past 600 ° C, the expansion of the scope of the adaptation of the electromagnet.

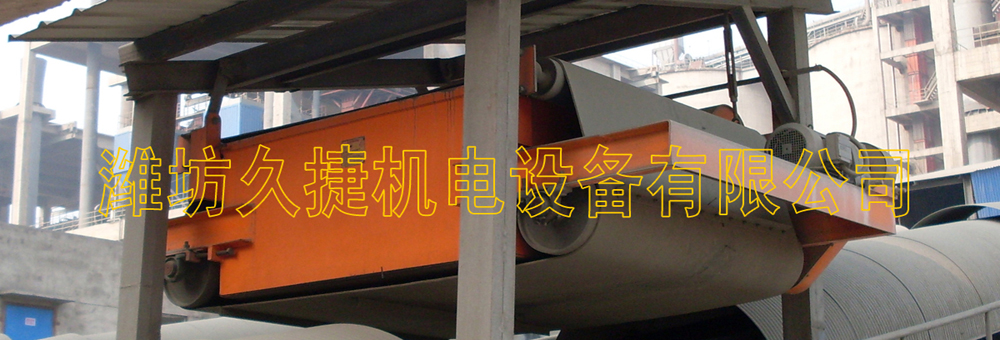

6, installation, operation, and maintenance is simple.Fourth, the main structure

1, the the lifting electromagnet magnetic circuit constituted by the bell cover, inside and outside pole, core and sucked matter.

2, the coil is placed in the bell cover, the non-magnetic protective plate composed of a sealed container, and # 168 fixed insulating oil.

3, the overall use of welded structures.

4, MW22, MW42-wire package structure.

5, MW92 series pole by the fixed magnetic pole and the movable magnetic pole two parts.

6, the high temperature electromagnet using a double radiant special insulation structure., Installation and commissioningUnpack the box, packing list inventory random technical documents, and carefully read the relevant documents.

2, according to the specific requirements, determine or select the lifting beam and installation.Check electrical performance of the solenoid (coil resistance and insulation resistance), dimensions, the supporting the spreader strength and size, if no problem can be installed.

4, check matching the power output of the control device and cable reel equipment parameters shall conform to the requirements of the electromagnet.

Join cable reel and solenoid cable connector connected, power is turned on, the electromagnet is a trial run of the 0.5-1h, such as abnormal phenomenon can be put into normal use.Sixth, use precautions

1, before use, should be measured electromagnet cold insulation resistance at room temperature, its value is not less than 0.5MΩ.

2, the magnet is not smooth on the suction object plane Do not energized before work the electromagnets do swim hammer use is strictly prohibited.Electromagnet electromagnet lifting should not to cut sprues and scrap, particularly large electromagnet suction and the electromagnets weight heavier material cutting head or scrap easily washed out the bottom of the radiant panel.

4, electromagnet should be placed on the center of gravity of the load as symmetrical as possible.

1) deadweight magnet = suck heavy capacity x (1 + eccentricity / pitch), so the lifting electromagnet between better spacing should be slightly larger. Two solenoid when the spacing between the two electromagnets small and eccentric large deadweight with a electromagnet same work extremely unsafe. For spacing expanded occasions, the operation should minimize the amount of eccentricity, safe and reliable.

2) for the degree is not easy to produce around longer steel electromagnet weight greater general TSU. In this way, the adsorption surface level is very important, should balance two layers of beams hanger. Except for special reasons, the use of four electromagnets associated with much smaller, easy to debug and use of the practice, this chain hoists like precision requirements.

3) When more than four sets of electromagnets combined with lifting, electromagnetic adsorption surface should be carefully adjusted to suit the actual conditions, otherwise it will appear the individual electromagnet not only does not work, but also weight plus add other electromagnet burden.

5, both associated with its pitch for the half of the material length.

6, requires high temperature material with high temperature electromagnet lifting, with room temperature electromagnet the lifting room temperature material, non-use room temperature electromagnets the lifting high temperature materials.

7 Do not stay in the solenoid to wait on the hot object. High temperature drops below 600 ℃ before working near the electromagnet electromagnet being sucked the temperature of the ultra-high temperature electromagnet by being sucked temperature drops below 700 ℃ before electromagnet near work.

8, when not in use, does not cause the electromagnet to stay in the high temperature zone lingered storage.

9, electromagnets and high-temperature object contact time as short as possible.

10, low power rate electromagnet can not make use of high power rate corresponding power rate must be chosen according to the specific circumstances of the electromagnet.

11, for ultra-high temperature electromagnet in the process of using the suction decreased or pole overheating should let electromagnet rest for some time, or electromagnet poles soaked in a ditch at a depth of 300mm of cooling.

12, electromagnet with the crane lifting to avoid smashed off and pull off the cable.

13, in operation, to periodically observe the voltage, current instruction value in the electromagnet on the control screen. Electromagnet excitation current should be in between the cold current and the thermal current. Voltage allows the error does not exceed ± 10%.

14, the electromagnet should be kept dry, after use, should be stored in a dry, ventilated, no harmful substances at.

15, regular checks of the chain, the pin wear.Selection ConsiderationsSuck transported material temperature is below 100 ° C, please use the normal temperature over 100 ℃, the choice of high-temperature type.

2, the power sustained rate of more than 60%, use high-frequency type.Water suction lift materials, please use the diving type (diving depth 100m). Submersible electromagnet parameters and normal temperature. Therefore, the sample is not listed, users need to dive type when ordering.

4, the ambient temperature: ambient temperature from -5 ℃ to 40 ℃, high temperature -5 ° C to 80 ℃. The altitude does not exceed 2000m.

5, ancillary equipment: the rectifier control equipment power (current) greater than or equal to a single one or more associated with cold and power (current).

Lifting electromagnetic knowledge

0086-536-3126667

china@magneticseparators.com.cn

Sales department phone:0086-536-3126667 Fax:0086-536-3128856 Add: No.112,Pianyi Road,Linqu County,Shandong Province,China.

ALL rights reserved:WEIFANG JIUJIE MACHINERY ELECTROMAGNETIC EQUIPMENT CO.,LTD 鲁ICP备12031234号-1

E-mail: china@magneticseparators.com.cn